BioMat Pavilion 2021 (LightPRO Shell)

The LightPRO Shell Pavilion is a lightweight structure that combines an active-bending gridshell made of natural fibre biocomposite profiles with a tensile membrane. The resulting system is a combination of two doubly curved surfaces that share a continuous beam outline. The outline is composed of two connected profiles that act as a beam, transferring forces from both systems to three anchor points attached to a superficial foundation.

BioMat Flat to Spatial Mockup 2020: Minimal Surface Modular Biocomposite Material

The Mock-up demonstrates a vision for modular sustainable architecture, where annually-renewable biomaterials are digitally additively-fabricated to produce minimal surface modular units, which are versatile and reusable in diverse geometric constellations.

Tailored Biocomposite Canopy 2019

The Tailored Biocomposite Mock-up, realized by the Department of Biobased Materials and Material Cycles in Architecture (BioMat), located at the Institute of Building Structures and Structural Design (ITKE), is a single-curved canopy, generatively designed as a lightweight structure of 225cm high and 125cm width. Mock-up was fabricated by Tailored Fibre Placement (TFP) of flax natural fibers moulded to biocomposite.

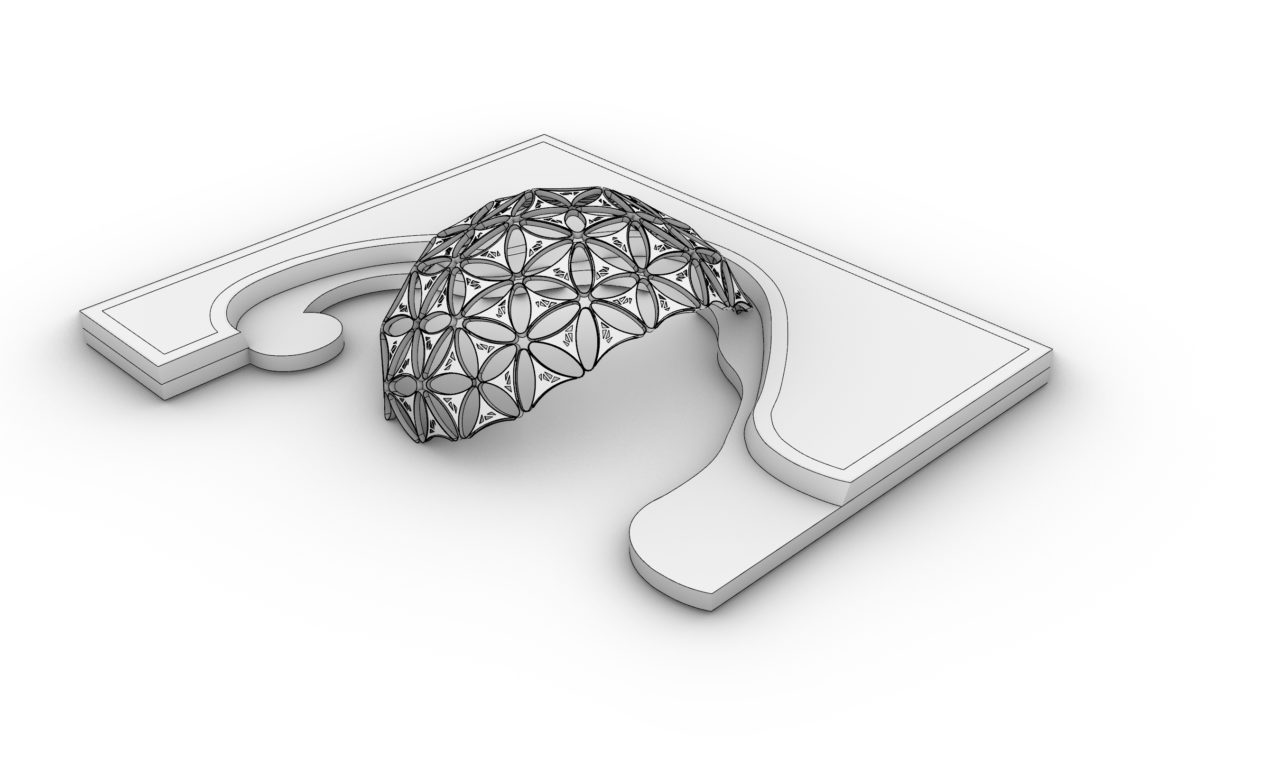

INTERLOCKING SHELL: Biomimetic Research Pavilion

BioMat B.Sc. 2018: Arzum Coban, Victoria Ivanova

The research pavilion was inspired by Diatoms. Diatoms are a unicellular type of Phytoplankton. Although they are unicellular, they can form colonies in the shapes of filaments or ribbons.

BioMat Pavilion 2018

On the 15thof August 2018, the official opening took place of the first experimental pavilion, realized by the department of Biobased Materials and Material Cycles in Architecture (BioMat), located at the Institute of Building Structures and Structural Design (ITKE) in the Faculty of Architecture and Urban Planning, University of Stuttgart.

Eco-Pavilion

A zero-waste ecological research pavilion of scale 1:1, made of 100% recycled materials and bio-based components.

Concept: Simulation of an architectural ecological space, ready for temporary usage, of minimum 5 years, with a complete cradle to cradle® concept

Cooperation: Architecture office Grosse in Stuttgart, 20 architecture students, 15 academic institutes and companies sponsorship

Planning and preparation: 6 months

Building duration: 4 days

Twining

More than 12 m long and 4 m width pavilion with height of 3 m is highly inspired by technic called twining. Twining is one of the oldest active bending technic, which constantly and broadly used in the bamboo products. It can strengthen the whole weaving structure and also highlight the beauty of the pattern. The idea was not merely applying this kind of weaving pattern on the shell structure, but to simplify it and find another combination. The concept respects properties of flexible board and give them a structural stiffness through its interweaving.

Triangulated Shelter

Concept gains an appearance of lightness and reduces the physical weight of the structure by dissolving the shell in triangular modules. Five or six of these triangles come together to pentagonal or hexagonal shape. Each side of the triangle consists of an originally planar stripe of flexible board with veneer on one side and textile on the other one. By these means, the material gets the necessary rigidity to work as a structural member of the pavilion but is still able to be bent to a certain degree. That is slightly bent. The still flexible connectors hold the triangles onto each other. After analysing of each component, students went through an optimisation process with the aim to limit the amount of different shapes and to simplify the geometry by using repeating elements.

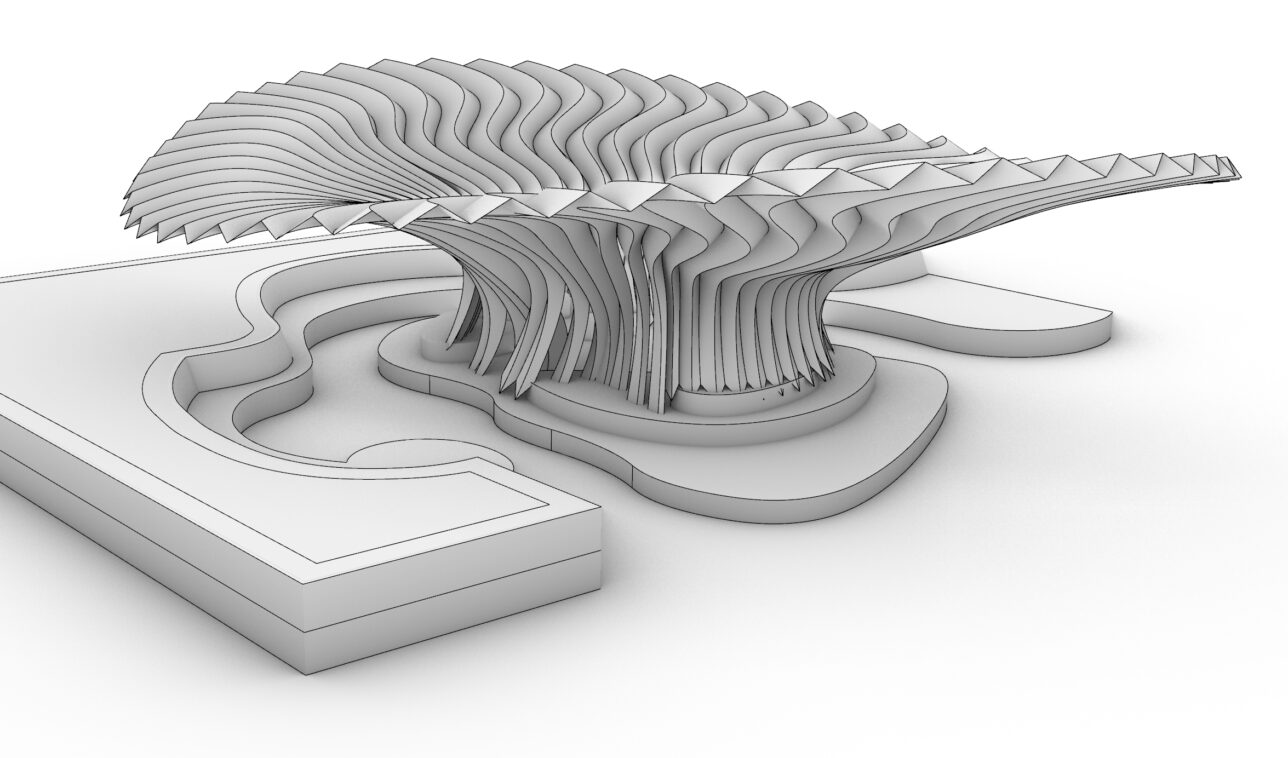

The Mushroom

The Mushroom is a research pavilion for a design project organised by the Institut für Tragkonstruktionen und konstruktives Entwerfen in Stuttgart. The main material of this pavilion is BioFlexi. It’s a flexible and biodegradable material with a lot of possibilities of use.

Main goal while designing this material was to mimic textures of mushrooms.

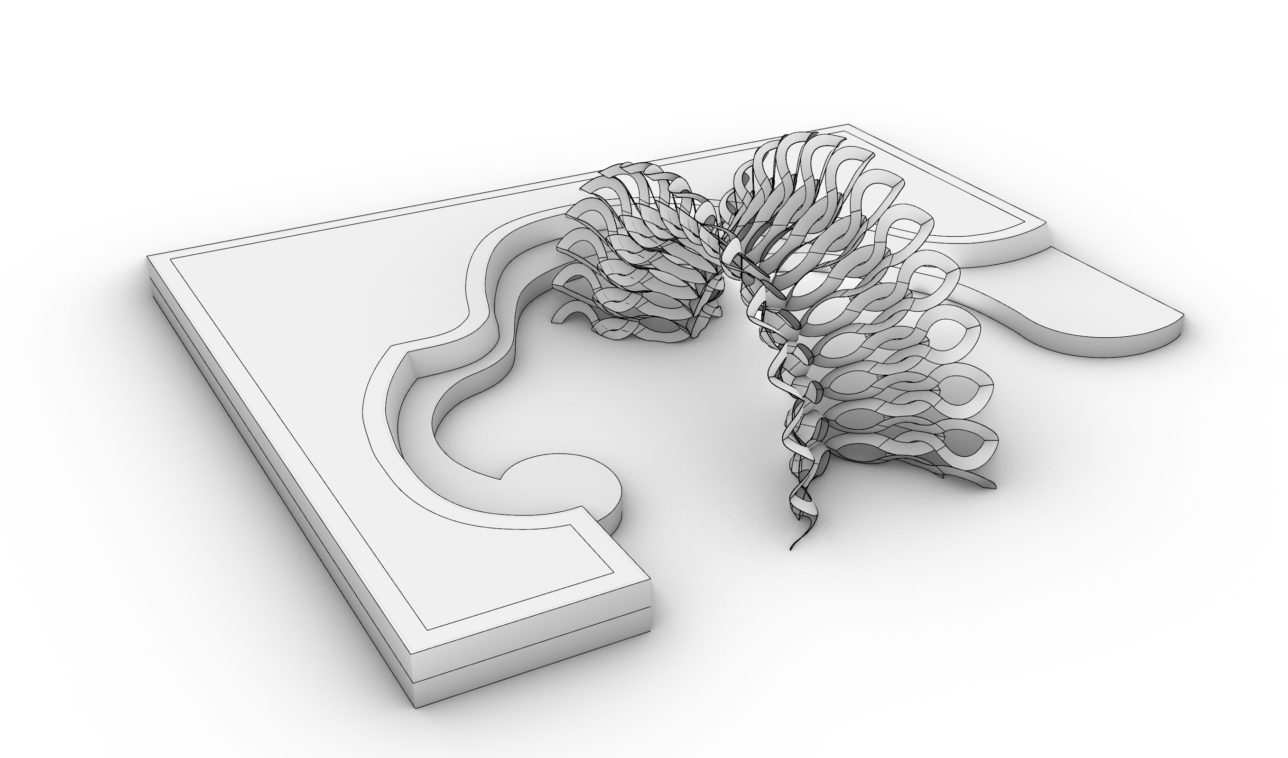

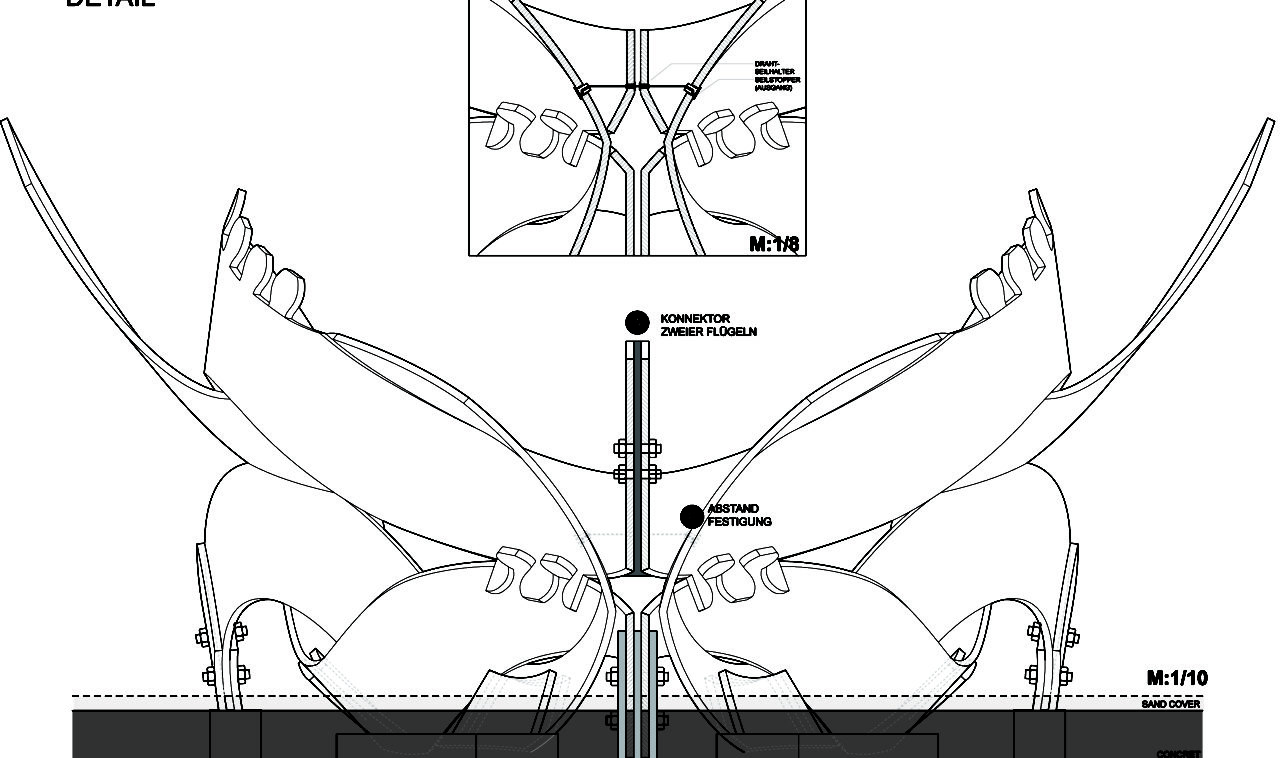

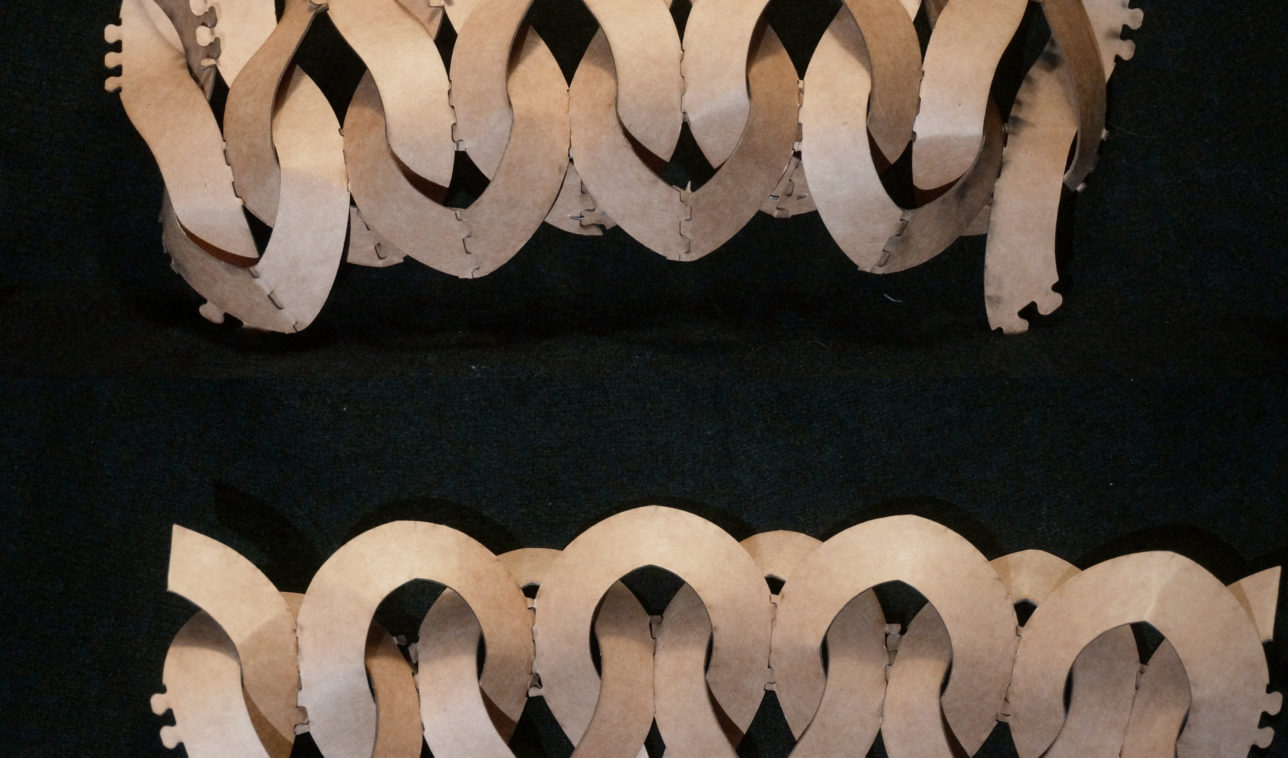

Stacking Cloud

Inspiration started with the microanalyses of raspberries and how the paricular berries stick together.The idea was to think up a system of volumetric elements, created by various components, to populate a shelter-like structure. By playing with materials, pen, paper and 3D, was developed an component based on four arched Möbius strips out of biocomposite flexible board. It gave some stability, but only after adding 3D veneer from both sides of flexible board, the component got stiff and ready for further structural development. Those componentes are modular and can be populated to almost any shape with optimal structural design