FibRfoldR

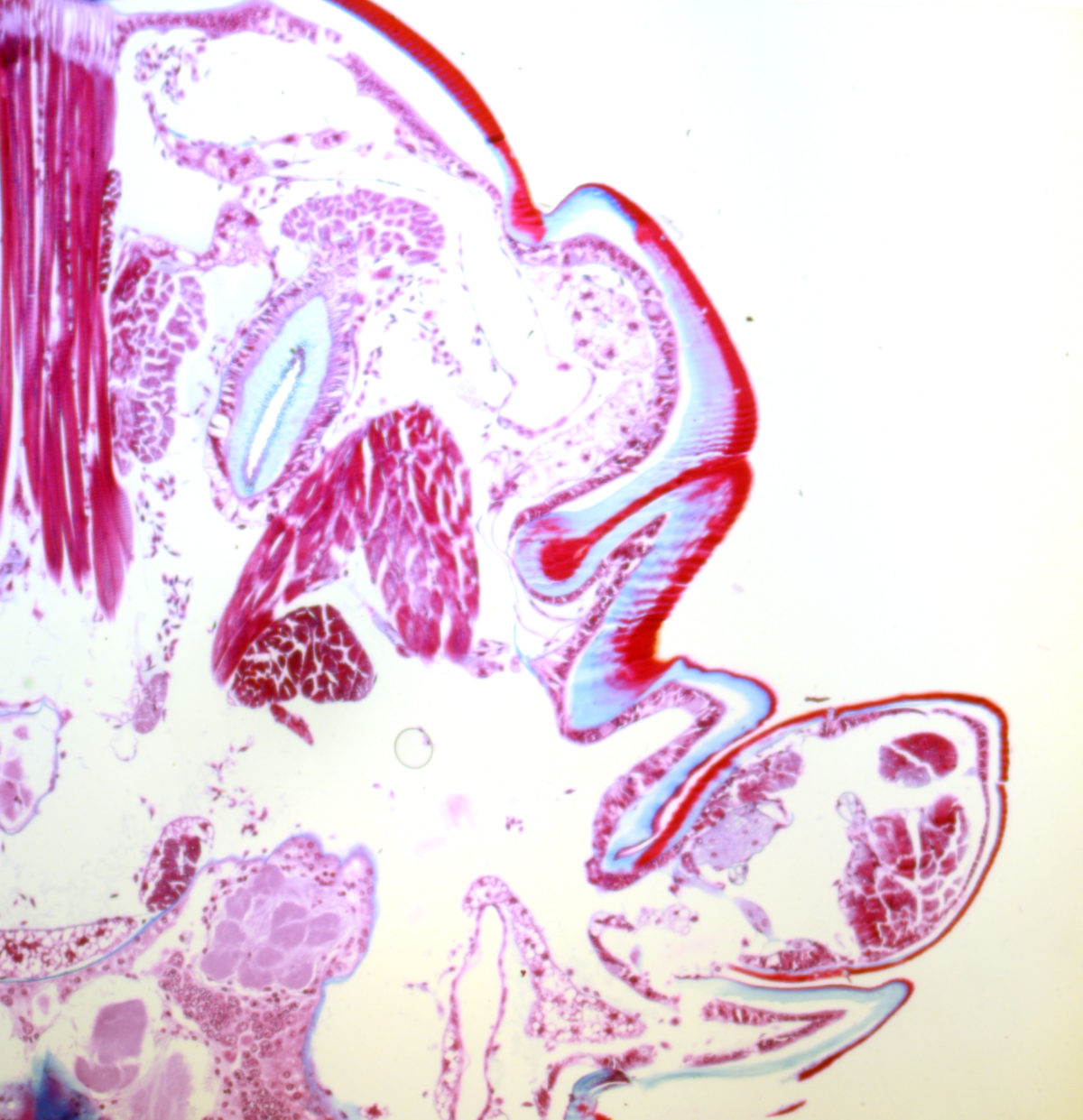

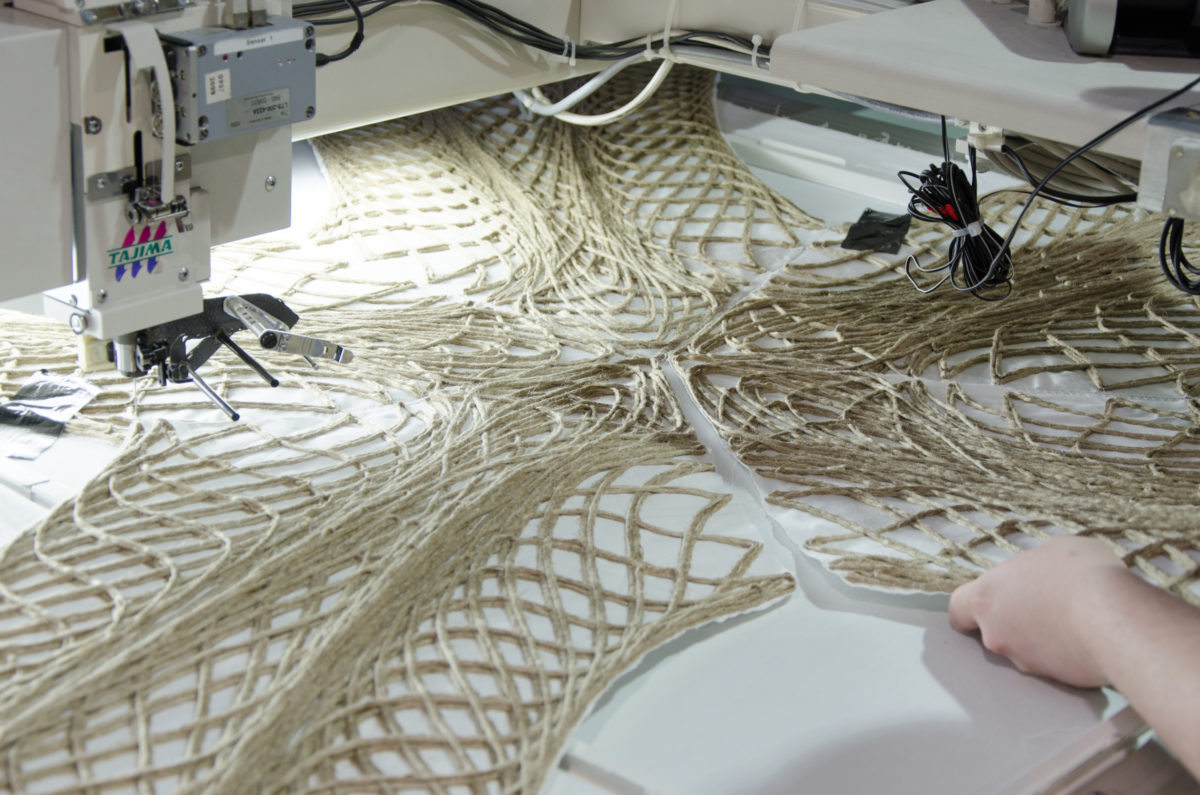

The aim is to eliminate the time consuming work of preparing extra form-work as well as the classical lamination process for mass customization. The idea is to produce a flat reinforcement preform, using tailored fibre placement fabrication and flax rovings, that is programmed to precisely fold into a spatial object without or with a minimal scaffolding. Using a parametric design tool for global form-finding and tool-path generation, as well as a CNC fabrication setup allows to mass customize a flat reinforcement layout. As a result, a wide variety of models can be produced without increasing the manufacturing effort. The advantages of the proposed design and fabrication system is tested in form of a stool.

Students: Okan Basnak, Maximilian Klammer, Gabriel Rihaczek,

With support of Benjamin Grisin, IFB University of Stuttgart

Tutor: Jan Petrš, Evgenia Spyridonos

Supervisor: Jun.-Prof. Dr.-Ing. Arch. Hanaa Dahy

Design Studio: Material and Structure, WS 19/20, University of Stuttgart.